Termoformado – TVP35

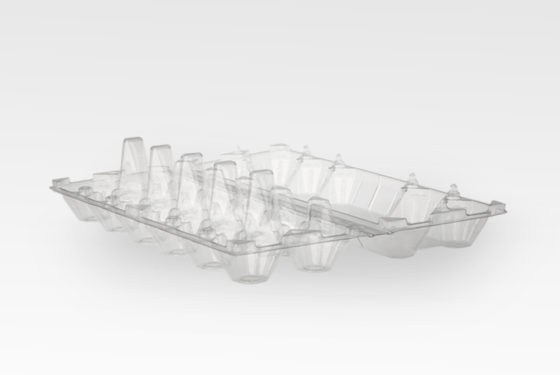

Automatic vacuum and pressure thermoforming machine with separate stations for thermoforming, die-cutting and vertical stacking of the final product in a conveyor belt.

Features

- Dedicated to the production of medium and long runs of small pieces.

- Working area of 500×350 mm.

- It allows the moulding of pieces of 70/80 mm height (above and below the film line respectively).

- Roll feeded.

- Film traction by chain conveyor.

- Film heating (patented system).

- Fixed heater equipped with ceramic resistances and a motorized roller shutter in stainless steel that allows to regulate the area of radiation.

- It improves the initial cycle efficiency after a stop, by avoiding the overheating of the area to be molded.

- Prevents heat dissipation, reducing electrical consumption.

- Vertical stacking station “from top to bottom”

- Simplicity of stacking and adjusting tooling.

- Possibility of using the same stacking tooling for different products.

- Savings in adjustment time and tooling costs.

- Pressure forming to produce more detailed pieces.

- Allows the installation of an additional punching station.

- PLC operated, touch-screen controlled.

- EU safety rules compliance.

Operation

The thermoforming machine is fed from a plastic roll. The film is heated in the heating module until it reaches the appropriate temperature depending on the type of plastic and then goes to the moulding station, cutting and finally, the pieces finishes in the vertical stacking station.

|

|||||

Videos:

| Hamer FV35 moldeadora automática |

Em caso de interesse nos nossos produtos e queiram fazer uma consulta sem qualquer compromisso, aguardamos pelo vosso contacto, por telefone, email ou preenchendo o formulário que se segue:

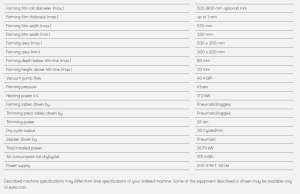

Características generales.

Características generales.