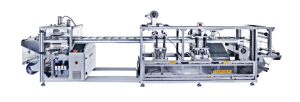

Blister packaging BPC 23

Automatic line machine suitable for manufacturing face-seal blister, full-sealed blister and full plastic blister.

Features

- Dedicated to the production of short and medium runs

- Low operating and maintenance cost.

- Quick tool set change-over, done by only one operator.

- PLC operated, touch-screen controlled.

- Steel-rule die cutter, which avoids misalignment in the cut.

- Film traction by chain conveyor.

- Monoblock chassis that does not require assembly at start-up.

- Optional automatic card feeder.

- EU safety rules compliance.

Operation

The BPC23 integrates all the necessary operations for the manufacture of the blister, from the thermoforming from a plastic roll, through the loading of the product, sealing, individual punching of each of the figures and expulsion of the finished blister.

|

|||||||||||||||||||||||||||||||||||||||||||||||||||

Ver Video da BPC23 no youtube:

| Hamer BPC23 Blisterpack machine |

Em caso de interesse nos nossos produtos e queiram fazer uma consulta sem qualquer compromisso, aguardamos pelo vosso contacto, por telefone, email ou preenchendo o formulário que se segue: